Update: 28 December 2018

Through this post we will briefly go through different aspects of 3D Modeling and Printing, and bring up some basic tips, techniques, and resources require to get started with 3D Modeling and printing parts and thereby try to answer some basic queries related to 3D Printing. These tips & tricks helped me to create, design and develop various physical parts for my Humanoid successfully. So let’s get to it!

#3D Modeling

“The key to understanding any people is in its art: its writing, painting, sculpture.” ― Louis L’Amour

3-D modeling is the use of software to create a virtual three-dimensional model of some physical object. 3-D modeling software generates a model through a variety of tools and approaches including:

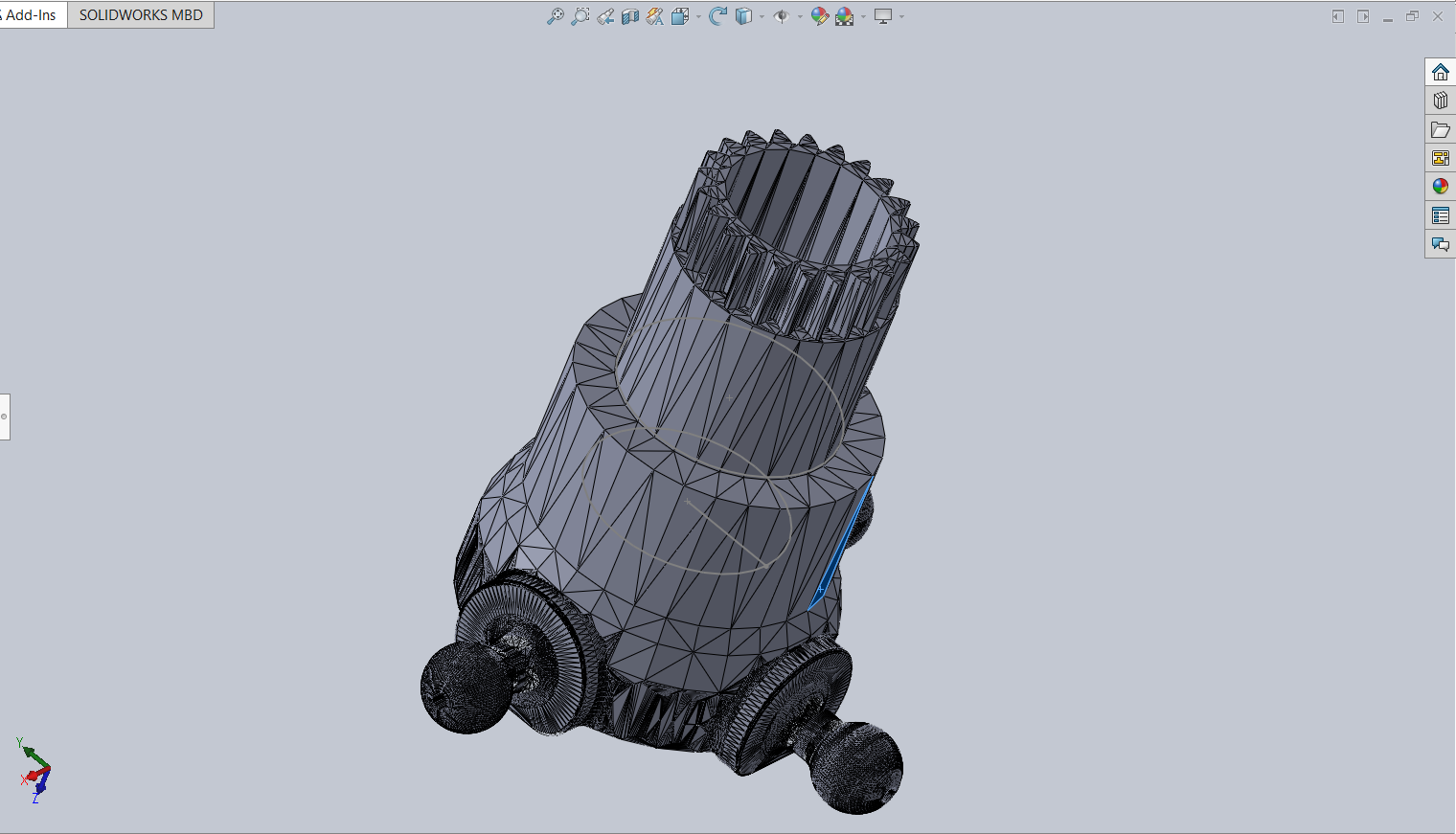

polygon-based shapes of a part in Solidworks

polygon-based shapes of a part in Solidworks

- simple polygons.

- 3-D primitives – simple polygon-based shapes, such as pyramids, cubes, spheres, cylinders, and cones.

- spline curves.

- NURBS (non-uniform rational b-spline) – smooth shapes defined by bezel curves, which are relatively computationally complex. 3D modeling is a precise workflow often involving the painstaking placement of individual vertices to achieve the correct contours of the desired object.

How do 3D Modeling works?

Basic Cube in Cinema4D

Basic Cube in Cinema4D

- An artist usually begins by generating some type of primitive like a cube, sphere, or plane. The primitive is just a starting shape to begin modeling. The artist will build upon this basic form and manipulate it using various modeling tools. For 3D modeling, it’s almost always a good idea to start simple and work towards complexity.

- The exterior of the mesh is composed of polygons which can be subdivided into smaller shapes to create more detail. These subdivisions are especially necessary if the 3D model is to be animated.

- Any joints that need to bend—such as a character’s knee or elbow—will need these additional polygons to ensure smooth motion.

- Several tools exist to speed up the modeling process. Most programs include a mirroring technique that lets the artist build a symmetrical model by only working on one half—or even one quarter—of the object. This is especially useful in character design as an artist only needs to model one side of the character and the software will mirror their work along the desired axis creating a perfectly symmetrical object.

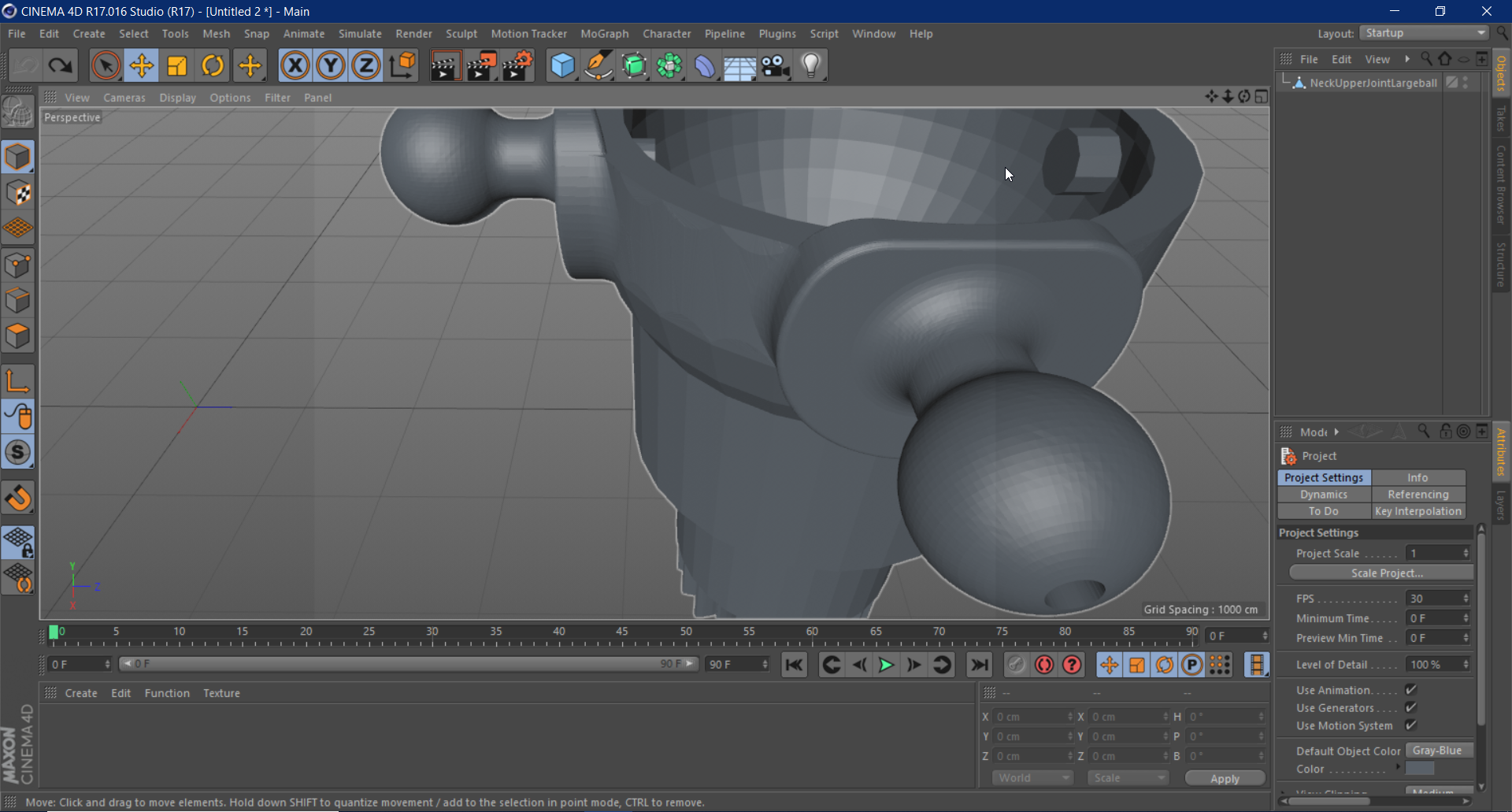

Textured View in Cinema4D

Textured View in Cinema4D - Once the model is complete the surface can be painted and textured. The texturing of models is beyond the scope of this post, but it is important to note that textures can be used to fake surface details.

Best 3D Modeling Software?

There’s no shortage of 3D modeling programs to choose from. Best of them according to me are:

- Solidworks

- Maya by Autodesk

- Cinema4D

- Blender

- SketchUp

But there are tons of other modeling programs out there so have a look in Google if you’re curious to find more.

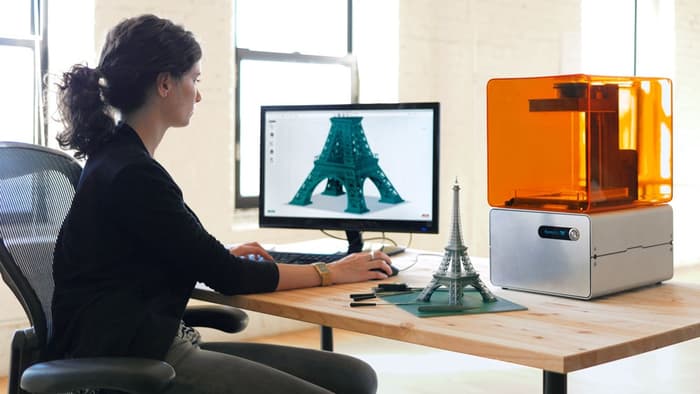

3D Printing

As the name implies, 3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process, an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object. 3D printing enables you to produce complex (functional) shapes using less material than traditional manufacturing methods. Initially, 3D printers were used as a rapid prototyping solution to make one or two quick physical samples giving the designers a chance to correct the flaws and modify the product. Prototyping still is the major usage of 3D printers but the developments in technology have made it possible to use this 3D printing beyond research and development stages and incorporate it into the manufacturing stage.

How Does 3D Printing Work?

- Modeling: As discussed above, It all starts with the creation of a 3D model on your computer. This digital design is, for instance, a CAD (Computer Aided Design) file. A 3D model is either created from the ground up with 3D modeling software or based on data generated with a 3D scanner.

- Slicing: Now that you have a 3D model, the next step is to prepare it in order to make it 3D printable. You will have to slice a 3D model in order to make it 3D printable. Slicing is dividing a 3D model into hundreds or thousands of horizontal layers and is done with slicing software. When your 3D model is sliced, you are ready to feed it to your 3D printer. This can be done via USB, SD or Wi-Fi. It really depends on what 3D printer brand you work with. When a file is uploaded in a 3D printer, the object is ready to be 3D printed layer by layer.

- Printing: 3D Printers use a laser or extruder (the material output part of the printer), that move along an X, Y and Z axis to build an object in three dimensions, wherein successive layers of material are laid down in different shapes. These layers can be only a few microns thick at a time. This is an advantage over the traditional method which uses a subtractive method where materials are cut or drilled from the mold. Using the additive process, layers of materials in liquid, solid or material form are fused together. 3D printers thus use additive manufacturing or direct digital manufacturing technology to produce a prototype of a product.

Using this new technology, a manufacturer can develop a working prototype in just a few hours compared to traditional prototyping. Ultimately, this results in saving time and cost. Especially since the additive manufacturing process also minimizes waste.

Types of 3D printers?

Material extrusion-based(FDM) 3D printers

Material extrusion-based(FDM) 3D printers

As of today, there are four distinct types of technologies used in 3D printers:

- Material extrusion-based(FDM) 3D printers

- Photopolymer printers

- Selective Deposition Lamination(SDL) printers

- Binding 3D printers

Most popular nowadays & commonly used 3D printers, one I use is Material extrusion-based 3D printers(FDM) as they’re cheaply available and easier to deal with, than other kinds.

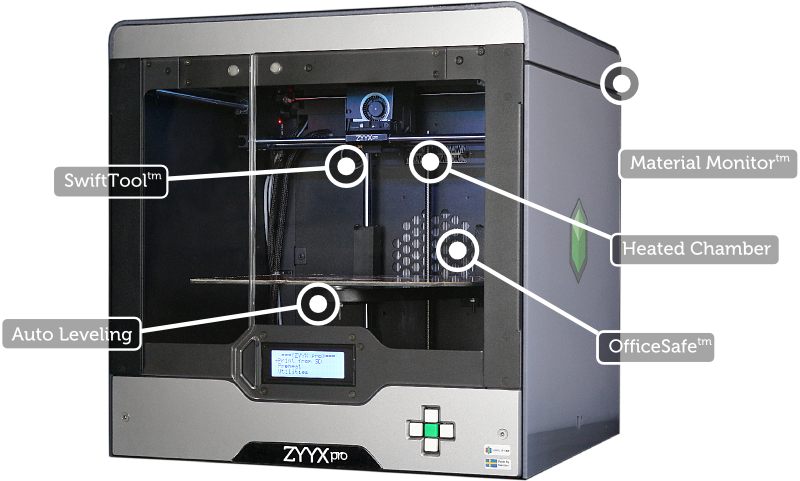

Best 3D printer?

It basically depends upon your budget, and size & scale of your Models, i.e. going to print on it. Other points to look for in 3D Printers while buying it are as follows:

- Printing Speed: To print a 3D object, printers need to work with a CAD file. Each printer then takes this file and prints the object layer by layer. Sometimes, an object also needs to be finished manually. File to finish speed is an important criterion to consider while choosing a 3D printer.

- Accuracy: Different printers have different accuracy. In general, the more accuracy you need, the costlier the printer. It is also important to consider part geometry, size and material shrinkage for production applications.

- Printer Technology: There are at least four types of technologies on which all the current 3D printers are based. It is important to understand which technology is suitable for your requirements.

- Raw Material: Currently, there is a bewildering array of raw materials available. Not each printer is suitable to handle all the material types. You should be aware of what your requirements before you finalize a 3D printer.

I’ve been using Creality 10S for over 1.5 years now and haven’t got any serious problems. But first, make sure to learn properly the basics of your 3D printer and YouTube is a great place to start. So, some the my favorite YouTube channels for 3D printing, are as follows:

These are many more awesome channels out there on YouTube too. Be sure to check them out too.

3D Slicer:

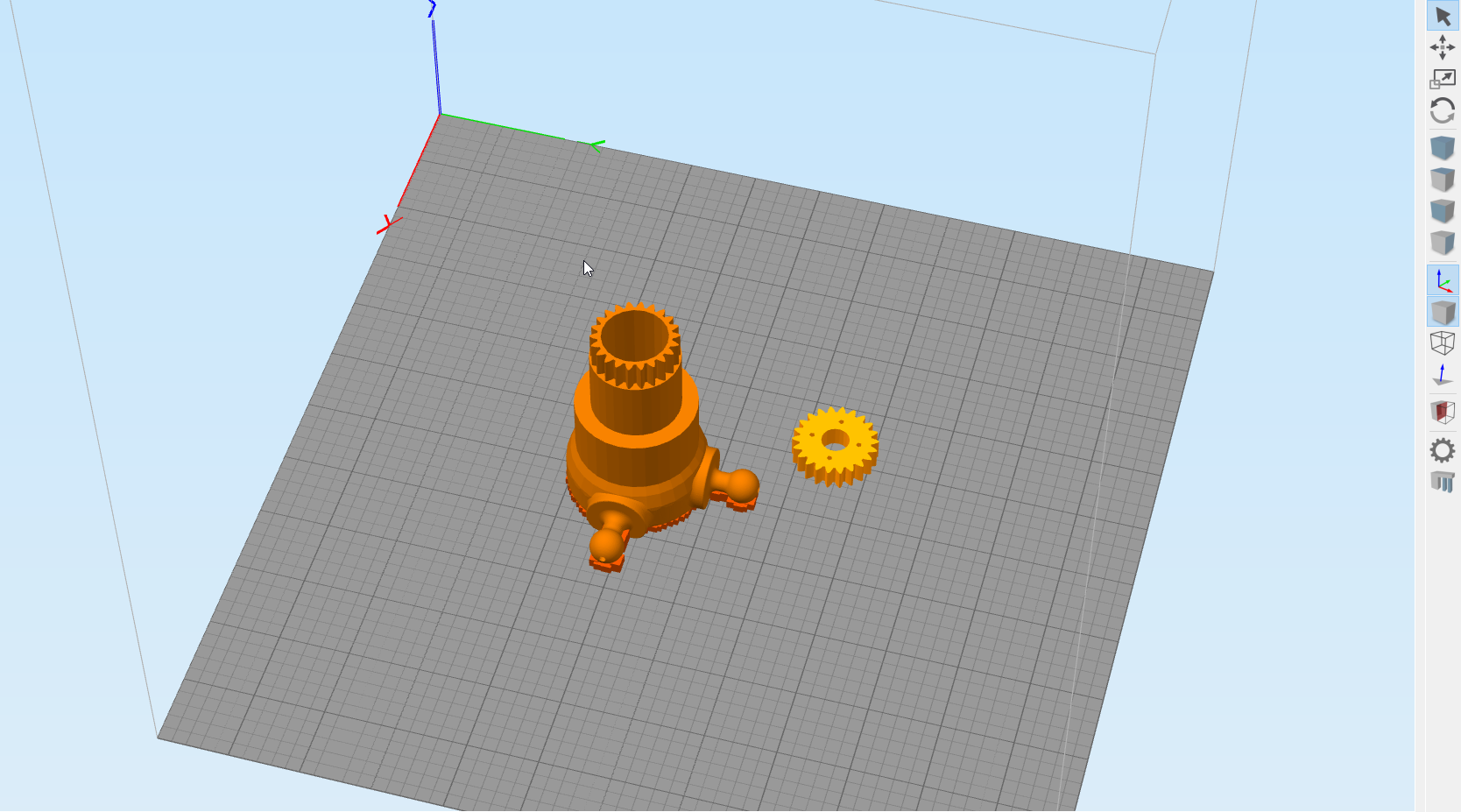

Simplify3D UI

Simplify3D UI

A 3D slicer is a piece of software, running on a computer. It acts as an interpreter for your 3D printer. You feed it a 3D file, usually, that’s an STL, M3F or OBJ file (which describe coordinates in a three-dimensional grid). The 3D slicer software then cuts the object in many horizontal layers and produces a path a print-head can follow – line by line, layer by layer.

3D slicer software will create:

- a toolpath based on the geometry of your STL-file.

- a percentage of infill to save 3D printing time and material.

- constructions of support material, if the geometry is difficult to print. These supports are meant to be removed after the print is finished.

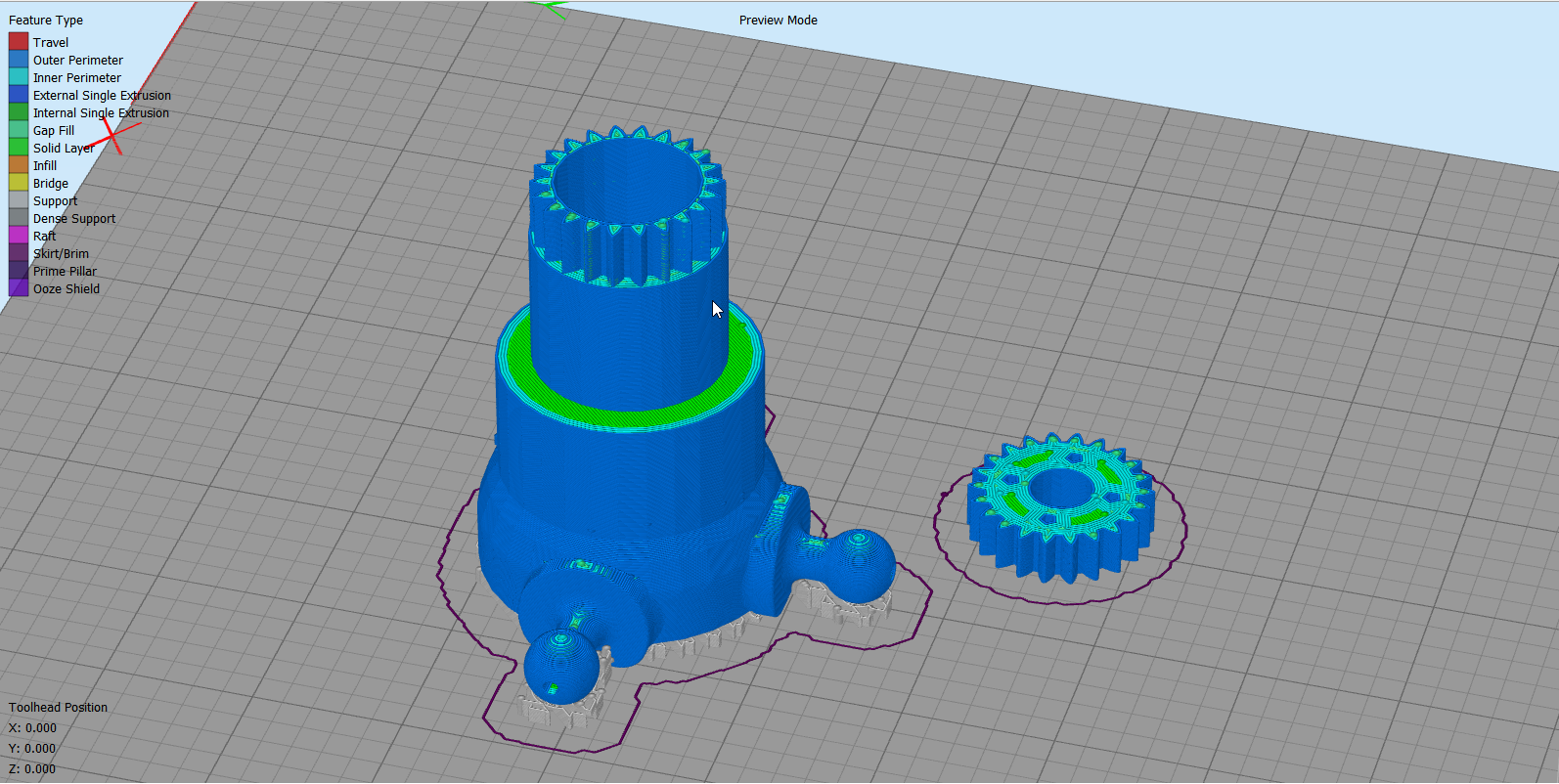

Humanoid 3D Printed part layer-by-layer information

Humanoid 3D Printed part layer-by-layer information

- After analyzing the file and offering you choices and settings, the software generates a ‘G-code’ file that‘s tailored for the machine you’re using. It describes coordinates, nozzle and bed temperatures, fan control, print-head speed, and other variables.

More information on this topic can be found below:

Best 3D Slicing Softwares?

To help you find the perfect Slicer Software, here’s a list of my favorite 3D slicer software tools:

- Ultimaker Cura

- Simplify3D

- Slic3r

- MakerBot Print

- Astroprint

More in-depth analysis can be found here

3D Printing materials:

3D Printing materials

3D Printing materials

Different types of materials can be used in additive manufacturing:

- polymers

- metals

- concrete

- ceramics

- carbon fiber

- wood

- paper

- and often edibles (e.g. chocolate)

Materials are often produced in wire feedstock (filament), powder form or liquid resin. All seven previously described 3D printing techniques, cover the use of these materials, although polymers are most commonly used and some additive techniques lend themselves towards the use of certain materials over others. Read more about which materials you can use for 3D printing on our 3D printer materials page.

Choosing a proper printing material along with the proper printer settings is the key to get a successful 3D print. I usually prefer polymers as they are cheaply available and more specifically I use PLA filament in polymers for printing most of my parts. As it produces pretty sturdy and tough parts if printed properly(but can brittle if not). Otherwise, you can go with ABS or Nylon for maximum durability in Polymers. There is some special filament out there too for specific purposes but they quite expensive and thus I avoid them. You easily find them by googling. More Information here:

Application of 3D printing?

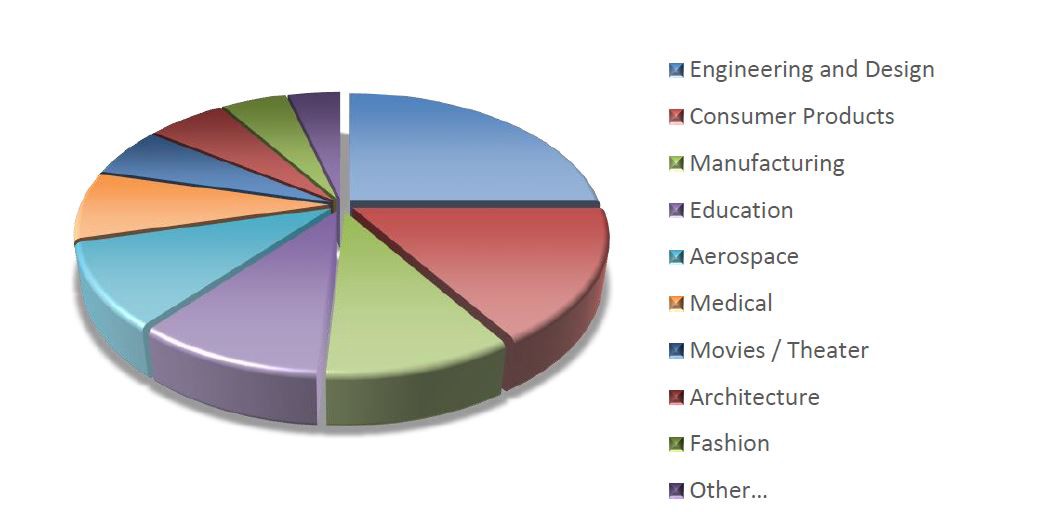

Application of 3D printing

Application of 3D printing

3D printing is being used in a wide range of fields including dentistry, fashion and of course high-end engineering industries like aerospace, automotive, specialty components, etc.

Conclusion:

Manav Humanoid 3D Printed part

Manav Humanoid 3D Printed part

Through this tutorial, we laid down foundation of different aspects of 3D printing and modeling in our mind. We also learn that:

“3D printing is an exciting and rewarding means of artistic self-expression.”

Though often daunting for beginners, the growing body of tutorials and learning resources means it’s never been easier to learn 3D modeling from scratch. Therefore, Now is the perfect time to get started on your own journey with printing and bring your unique ideas to life.

Hey there, Hope you enjoy reading this article. If so, Share it with your family & friends! So Stay Tuned and Stay Creative ;)